Search

CRUSH, SCREEN, EXCEL

The crushing and screening equipment market — which is driven by aggregate and construction industries, road projects, and railway lines — is believed to grow at a faster pace.

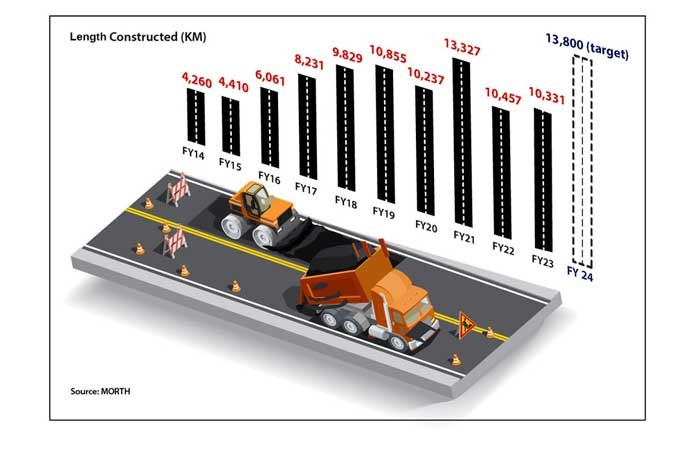

Will the Road construction target be achieved in 2023-24?

The road sector is suffering from immobility! Surprised?

Two steps ahead: The Vögele Dash 5 road pavers

The future in road building is here with Vögele’s latest-generation SUPER 1900-5(i) and SUPER 2100-5(i) road pavers.

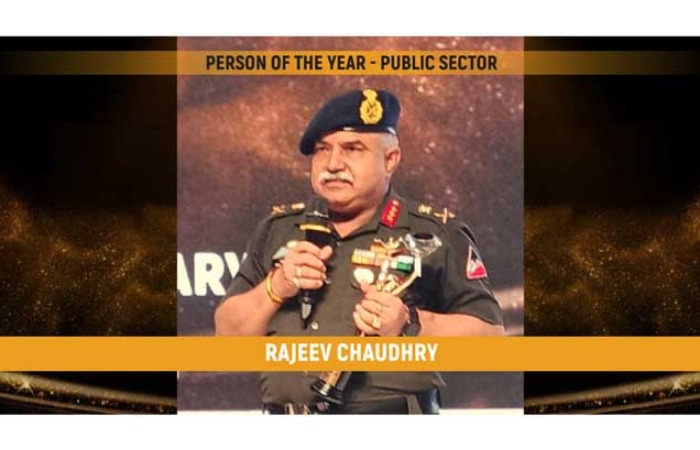

BRO Lt Gen Rajeev Chaudhry is CW Man of the Year - Public Sector

Lt Gen Chaudhry was awarded at the 19th CONSTRUCTION WORLD Annual Awards.

Low-cost, high-quality road REHABILITATIoN

The Wirtgen cold recycler and soil stabiliser WR 240 rehabilitates the 22-km road between Hapur and Kithore.

Crushing capacity creation needed

Road Transport and Highways Minister Nitin Gadkari informed in Lok Sabha that projects for constructing 6,320 km of road have been awarded under the first phase of the Bharatmala project, with the financial implication estimated to be Rs 1.44 trillion.

Saving cost of transportation

Crushing on site provides lower cost and greater efficiency. In fact, crusher and screening buckets attached to excavators and other earthmoving equipment allow materials to be processed for reuse, right where they are being extracted.

We would showcase innovations across all our four brands

With the infrastructure development polices of this government, there is good demand and growth for the CE industry. The difference from last bC India, is that two years back, the new government in place had ambitious plans to develop the road sector. Now the plans are being executed well, and due to this there is an increase in demand for equipment.

RAP Essential in Asphalt Plants

Asphalt mix production has had a long and rapid journey of redefinitions over the past decade, to allow the incorporation of RAP recycling. This procedure is now gaining acceptance in Indian markets.

Efficiency Matters

Globally, the past decade saw amazing developments in the hot- mix production technology. In India too, with the entry of global players, OEMs have geared up to offer advanced plants that can produce a variety of mixes - be it low energy / low-temperature asphalt mixes, warm / cold mixes, high percentage RAP mix, high recycling technology

Machine Control Technologies

There is a tremendous potential for machine control technology particularly in India as we are a developing nation with huge mass of natural resources and nearly 70 per cent of infrastructure is yet to be built and developed.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com